Picture this.

You've just spent months (or even years) developing a piece of tech that could change the world.

It's your baby, your pride and joy.

But then you realise this delicate marvel needs to survive in the real world, where it might get knocked about, rained on, or baked in the sun. That's where protective housings come in.

These aren't just fancy boxes.

They're the unsung heroes that keep our gadgets ticking, our sensors sensing, and our tech... well, teching. But designing these protective shells isn't as simple as wrapping your device in bubble wrap and hoping for the best.

It's not just about wrapping tech in bubble wrap.

When we're designing housings for high-tech gear, we're playing a constant game of tug-of-war. On one side, we've got protection - keeping all those sensitive bits safe from harm.

On the other, we've got functionality - making sure the tech can still do its job without a hitch. And let's not forget about making it look good too, because who said practical can't be pretty?

But before we dive into how we solve these puzzles, let's take a look at the main headaches we face when designing these tech-armours.

Water, dust, and dirt are the sworn enemies of electronics. One drop in the wrong place, and it's game over for your fancy gadget. Our job is to create a fortress that keeps these invaders out, without turning your device into Fort Knox.

For example, in a project for Industrial Monitoring Systems, we designed an enclosure to monitor fluid cleanliness. The challenge was to create a modern-looking, premium enclosure that met stringent IP65 rating requirements for dust and water resistance.

Electronics and heat go together like ice cream and summer - it's a melty mess waiting to happen. The trick is finding ways to keep things cool without compromising on protection.

4D’s product designer Lorenzo emphasises, “High-tech devices often generate significant heat due to powerful processors, GPUs, and other electronic components. Managing this heat effectively is crucial to maintaining performance and longevity.”

For wireless tech, a metal case can be like kryptonite to Superman - it can weaken or block signals entirely. We need to find materials that offer protection without turning your device into a dead zone.

Imagine having to break into Fort Knox every time you needed to change a battery. Not ideal, right? We need to make housings that keep the baddies out but still let the good guys (that's you) in when needed.

Let's face it, we all judge a book by its cover sometimes. Your cutting-edge tech deserves a home that's just as impressive on the outside as the gadgetry is on the inside.

Choosing the right materials is crucial for balancing durability, weight, cost, and other performance factors. Materials must often be lightweight yet strong, such as aluminium, magnesium alloys, or advanced polymers.

They should also provide the necessary insulation, conductivity, or shielding without adding unnecessary bulk or weight.

Now that we've looked at the problems, let's roll up our sleeves and dig into the clever ways we're solving them.

We're not just picking materials willy-nilly. We're choosing superstars like aluminium that can protect your tech and help it keep its cool.

Or high-tech plastics that are tough as nails but won't mess with your WiFi. It's like finding a bodyguard who's also a good listener.

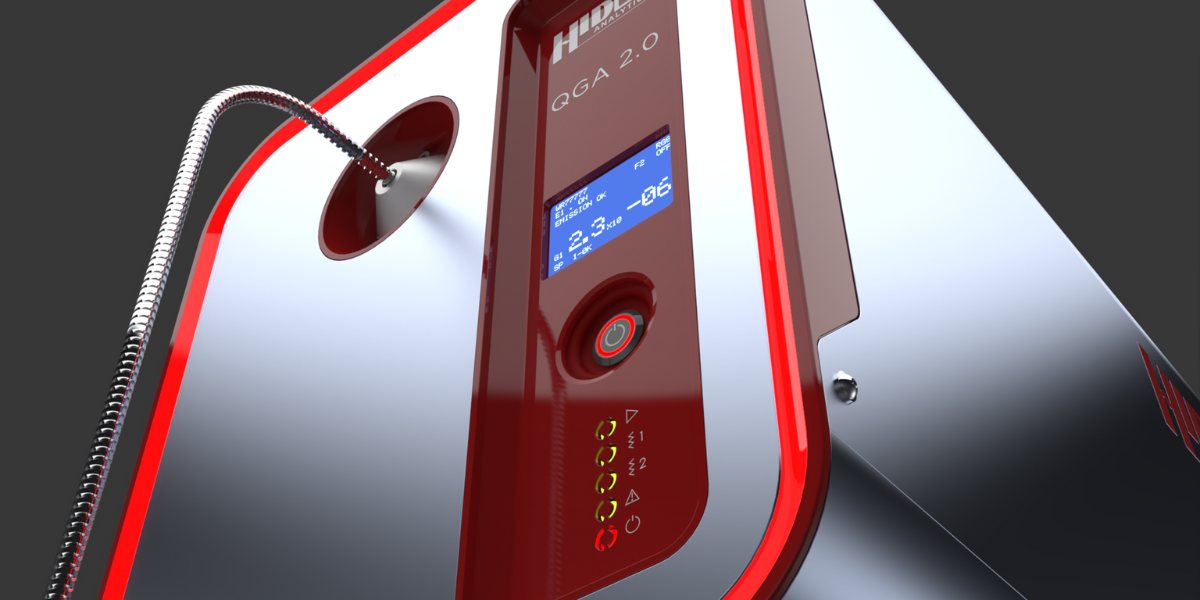

This was crucial in the QGA-2 project for Hiden Analytical, which required a careful balance of material properties to protect sensitive analytical equipment while maintaining optimal performance.

We use fancy sealing systems that would make a submarine jealous. Things like IP68-rated enclosures with one-piece silica gel seals. In plain English? They keep water and dust out, even if your device decides to go for a swim.

To stop your tech from breaking a sweat, we build in clever cooling systems. Think of them as built-in air con for your gadgets. We might add heat sinks (they're like radiators for electronics), vents in just the right places, or even active cooling for those extra hot-headed devices.

Sometimes, one size doesn't fit all. So we design housings that are a bit like LEGO - modular and customisable. This means they can adapt to different needs and make repairs a doddle. It's like having a Swiss Army Knife, but for tech protection.

We use smart venting solutions that let air in but keep water out. It's a bit like giving your device a set of gills. This stops condensation building up inside, which is especially handy for tech that likes to live outdoors.

For tech that needs to stay connected, we get creative. We might use selective shielding, leaving some areas 'signal-friendly'. Or we might add external antenna options. It's all about finding the sweet spot between protection and connection.

We always keep the end-user in mind. That means making sure there's enough space inside for tinkering, adding clear labels, and sometimes even instructions. Because a protective housing shouldn't need a PhD to operate.

This was exemplified in our project for Micrima, where we designed a breast cancer screening machine enclosure. The task was to create a design that looked soft and approachable to improve the patient's experience, as breast cancer screening can be quite daunting for many women.

Even the best design can fail if it cannot be manufactured efficiently and consistently. We always consider manufacturing processes like injection moulding, sheet metal fabrication, CNC machining, or 3D printing.

The enclosure design should allow for ease of assembly, cost-effective production, and scalability without sacrificing quality.

Advanced technology products often have high expectations for reliability and longevity, especially in critical applications. We design enclosures to protect internal components from physical shock, vibration, and long-term wear and tear.

Gone are the days when a sturdy plastic shell was enough to keep our gadgets safe. The protective housings of tomorrow are set to be smart, adaptive, and almost alive in their responsiveness.

Imagine enclosures that can change their properties on demand, becoming more heat-conductive when things get too hot or adjusting their structure to boost signal strength when connectivity is weak. It's like giving your device a chameleon-like superpower.

But that's just the beginning. Some of the brightest minds in materials science are working on coatings that can heal themselves, patching up minor scratches and dings without any human intervention. It's as if we're giving our devices' casings the regenerative powers of a superhero.

Energy is always a hot topic in the tech world, and protective housings are getting in on the action too. We're seeing the development of enclosures that can generate their own power, harvesting energy from light, movement, or even heat. Picture a phone case that charges your device just by sitting in your sun-drenched pocket or a fitness tracker that never needs plugging in because its housing captures energy from your movements.

As our devices become more flexible, so too must their protection. The rigid cases of yesterday are giving way to housings that can bend, fold, and stretch without compromising on safety. It's like teaching an old dog new tricks, except the dog is your tech's protective shell, and the tricks involve yoga-like flexibility.

But it's not all about flexibility and fancy features. As we push technology into ever more extreme environments, from the depths of the ocean to the vacuum of space, we're developing ultra-specialised housings that can withstand crushing pressures, extreme temperatures, and even cosmic radiation. These aren't just protective cases; they're high-tech armour for our most adventurous devices.

As sustainability becomes increasingly important, there is pressure to design enclosures that are environmentally friendly. This involves using recyclable materials, designing for disassembly, reducing waste during production, and considering the product's end-of-life impact.

Soon, the case protecting your phone might be as compostable as your takeaway coffee cup – good for your tech and good for the planet.

Artificial Intelligence is also making its mark, lending a silicon hand in designing these futuristic enclosures. AI systems can churn through thousands of design iterations faster than you can say "protective housing", coming up with optimised designs that might never have occurred to human engineers.

At the microscopic level, nanotechnology is set to revolutionise surface protection. Scientists are developing nanotech coatings that can repel water, resist scratches, and even kill bacteria. It's like giving your device's housing an invisible force field.

As our gadgets continue to get smarter, smaller, and more powerful, the ways we protect them are becoming equally clever and multifaceted. The humble housing is evolving from a simple protective shell into an intelligent, adaptive, and sustainable solution that's an integral part of the device itself.

So, the next time you pick up your phone or power up your laptop, take a moment to appreciate its protective housing. That unassuming exterior might soon be doing a whole lot more than just keeping your tech safe from bumps and splashes.

In the world of tech protection, the future is looking bright, smart, and incredibly resilient.

In the end though, designing protective housings for advanced tech is a bit like being a parent. We need to keep our 'kids' safe, while still letting them fulfil their potential and look good doing it.

As Lorenzo notes, “Designing enclosures for high-tech products is a balancing act between multiple factors. Creating a successful enclosure requires skills in areas such as industrial design, design engineering, and design for manufacture.

These core elements are the main drivers in creating a product that meets all technical requirements while also being user-friendly, cost-effective, and aesthetically pleasing.”

It's a challenge, but it's one that pushes us to be more creative, more innovative, and ultimately, to help amazing tech make it safely into the world where it can make a difference.